In an ideal world, buildings operate precisely as their designers intended—seamlessly regulating internal temperatures, managing humidity, and delivering thermal comfort efficiently and affordably. However, in the real world, HVAC systems rarely perform to their full potential. Despite good intentions and robust designs, the journey from concept to comfort is frequently marred by assumptions, shortfalls in commissioning, and a lack of ongoing oversight. This article explores the full lifecycle of HVAC commissioning, from the initial design through to post-construction handover, and into the essential realm of continuous commissioning and seasonal tuning. It also outlines how Asset Assess helps clients recalibrate expectations through data, visibility, and long-term performance management.

1. The Design Phase: The First Mismatch

Every building begins with a vision—usually involving an ambitious energy model, peak performance on the hottest and coldest days, and compliance with energy and comfort standards. However, designs are typically based on idealised scenarios, not the actual operational profile of a building once it’s occupied.

Engineering teams design for peak day conditions—the hottest day of summer, the coldest winter morning—but buildings spend the vast majority of their life operating far from these extremes. Worse still, the original design rarely considers actual occupancy, tenant use patterns, equipment loads, or staggered fitouts, meaning the assumptions baked into the design can be off by significant margins once the building is in use.

This disconnect between design intent and real-world usage creates the first calibration gap—one that sets the stage for underperformance.

2. Construction & Initial Commissioning: A Rushed Reality

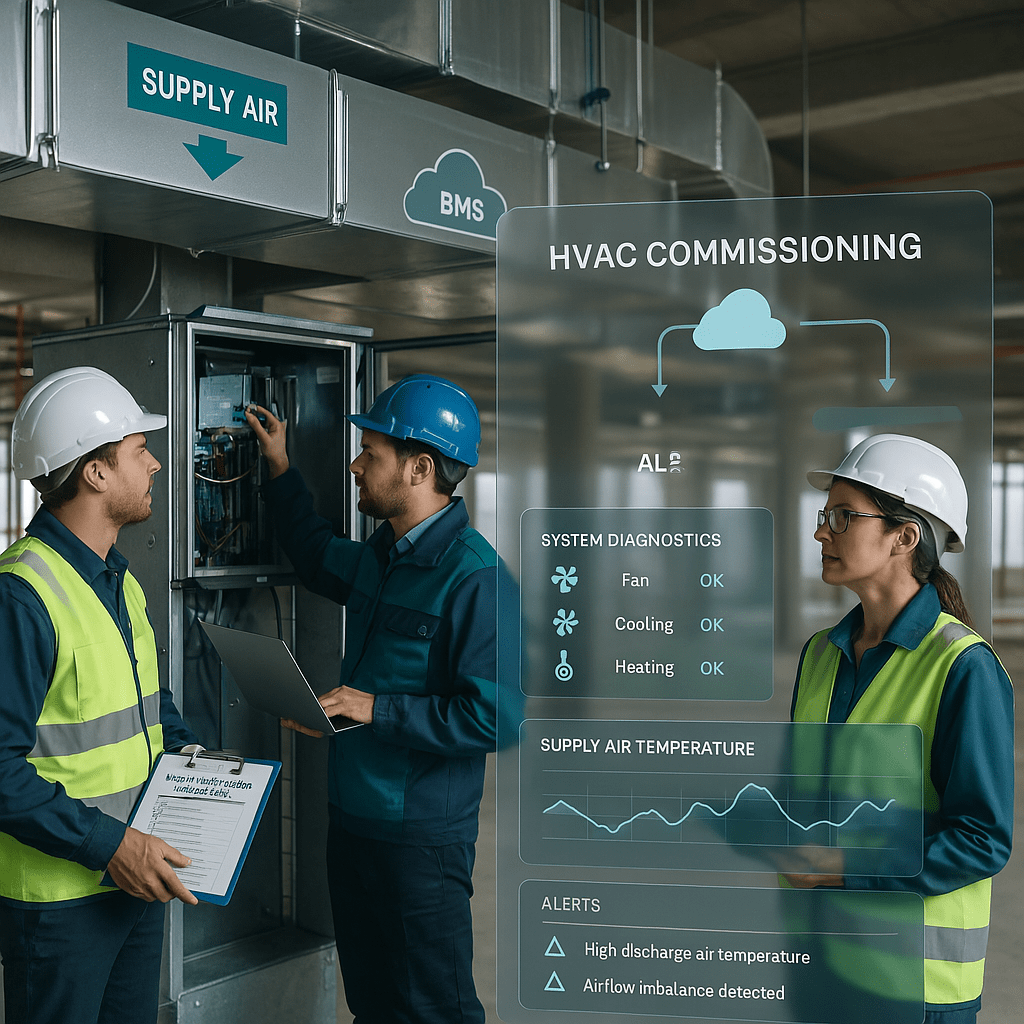

HVAC systems are among the most complex subsystems to commission in a building. A truly successful commissioning process requires time, budget, coordination, and precision. In reality, initial commissioning is often compromised by:

- Compressed timelines at the end of projects

- Incomplete tenancy fitouts

- Budget pressures that de-prioritise detailed system testing

- Unverified BMS configurations

- Inadequate point-to-point testing

As a result, systems are handed over with unresolved issues: valves and dampers wired incorrectly, reverse-acting actuators, systems operating in override or manual mode, and airside or waterside components that fail to meet design flows. At Asset Assess, we’ve repeatedly uncovered BMS points that were incorrectly referenced—controlling the wrong systems or providing faulty data for energy metering or occupancy control.

The result? A system that looks good on paper but fails in practice.

3. Fitout Integration: The Forgotten Commissioning

Adding to the complexity, tenant fitouts—often staged and varied—are treated as discrete projects with their own commissioning scope. However, these systems are usually not fully integrated back into the base building, leading to systemic inefficiencies:

- BMS controls overridden manually and never reset

- Valves left stuck or modulating incorrectly

- Systems running after hours or outside occupied times

- Sensor drift going undetected

Before long, a building originally designed to be efficient would likely be operating at 30% higher energy use than expected. And this excess consumption isn’t just costly—it often goes unnoticed until utility bills start raising eyebrows.

The Solution: Continuous Commissioning with Asset Assess

This is where Asset Assess provides game-changing value. Our platform ensures that commissioning is not a one-time event but an ongoing process of optimisation.

We approach commissioning—and recommissioning—not as isolated projects but as part of a building’s operational DNA.

Here’s how:

BMS-Agnostic, Service Provider Neutral

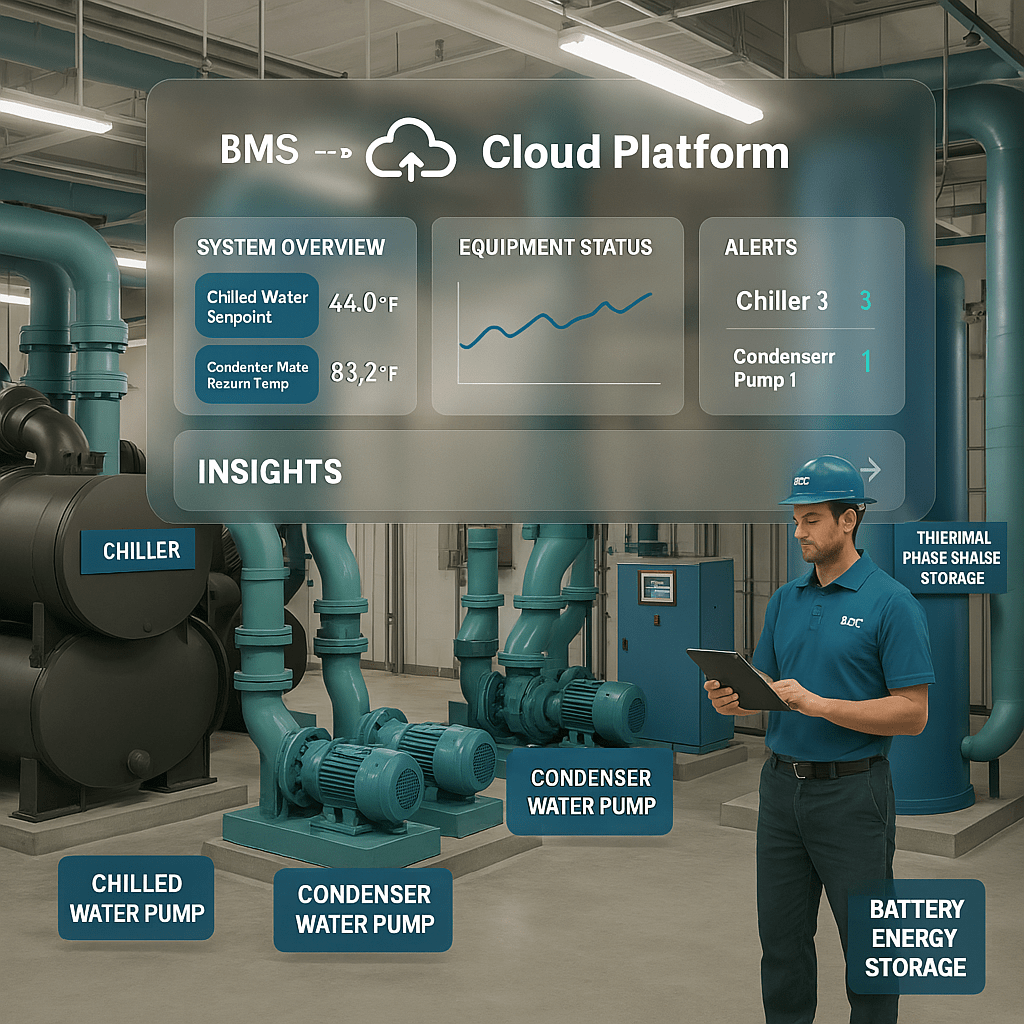

We work independently of any BMS vendor or mechanical contractor, meaning we stay with the building, not the service provider. Our analytics platform connects to the BMS and extracts granular 5-minute data from every sensed and controlled point—pumps, chillers, fans, valves, and more—establishing a living, breathing model of the building’s actual performance. We can extend that to a single pane of glass assessability to a whole portfolio of buildings across a city, state country or the globe.

During Initial Commissioning

Our platform can uncover and document:

- Incorrectly referenced BMS points

- Systems operating in reverse or outside specification

- Sequence of operations mismatches

- Uncommissioned or non-functional energy meters

- Schedule errors and unresponsive actuators

This allows targeted rectification during or immediately after handover—before issues become baked into the building’s operation.

Ongoing & Seasonal Commissioning

With automated Fault Detection & Diagnostics (FDD), Asset Assess identifies:

- Systems running after-hours

- Simultaneous heating and cooling

- Sensor faults and calibration issues

- Equipment that is failing or underperforming

- Energy wastage through operational inefficiencies

Because we sample data every five minutes, we see performance trends in real time, flagging issues long before they escalate into costly failures.

Lifecycle Planning with Real Use Data

When it comes time to replace major plant, Asset Assess can provide the actual load profiles, runtimes, and usage trends, so replacement decisions are evidence-based, not assumption-based. This helps optimise capital expenditure and reduce the risk of over- or under-sizing.

A New Expectation for Performance

At Asset Assess, we believe commissioning should be continuous, data-driven, and integrated into the entire building lifecycle. Our tools and expertise ensure the intent of the original design is met—even exceeded—by constantly tuning, recalibrating, and verifying the performance of building systems in real time.

By shifting the mindset from “set and forget” to “commission and keep improving,” facilities teams can deliver better comfort, lower operating costs, and smarter capital planning.

Let’s stop accepting underperformance as inevitable. Let’s start calibrating expectations.

Want to learn more about how Asset Assess can support your next project or help optimise your existing facility?

Contact us for a platform demo or case study today.

Leave a comment